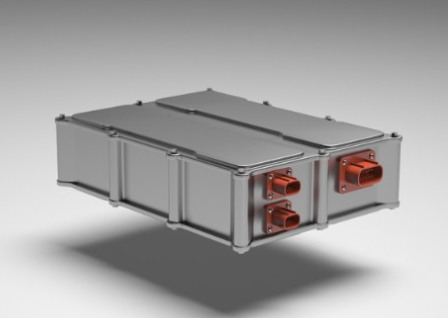

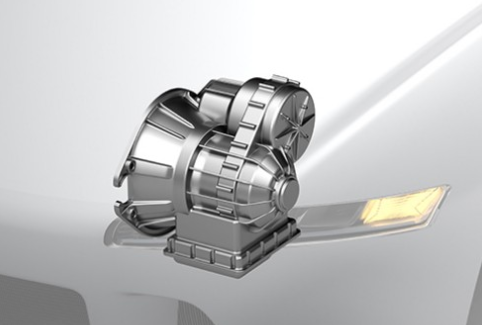

PPS

PPS (Polyphenylene Sulfide) is a high-performance specialty engineering plastic with excellent overall properties, including high strength, high rigidity, good long-term heat resistance, exceptional chemical resistance, good electrical characteristics, good dimensional stability, and maintained physical properties under high temperature and high humidity conditions. PPS achieves a UL 94-V0 flame rating without the need for flame retardants. We offer commonly seen cross-linked PPS (brown) and linear PPS (beige) on the market, as well as a hybrid material of cross-linked + linear PPS. Cross-linked PPS is known for its high rigidity and cost advantage over linear PPS, while linear PPS offers high toughness and low gas content.

Available material solutions include:

1.Glass Fiber Reinforced Grade: Enhanced with glass fiber for improved strength and stiffness.

2.Glass Fiber + Inorganic Filler Reinforced Grade: Combination of glass fiber and inorganic filler for enhanced properties.

3.Low Chlorine Content Grade (Cl < 900ppm): Ensures low chlorine content for specific applications.

4.High Toughness Grade (Elastomer Alloy): Provides high toughness for demanding applications.

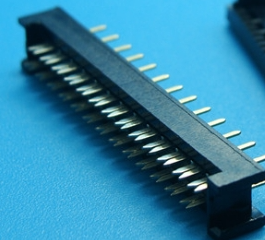

5.High CTI Grade (CTI=0): Ensures high Comparative Tracking Index for electrical applications.

6.High Adhesion to Epoxy Resin Grade (Specialized for Thin Film Capacitors): Designed for applications requiring strong adhesion to epoxy resin.